Concretex Building System

In 1985, Concretex invented the Concretex Building System, a modular building technology using custom lightweight precast concrete panels. These are assembled as required, allowing for the system to adapt to customer requirements. The resulting homes are constructed quickly and of high quality components. The system was patented and was awarded the Mantag Certificate from the Agrèment Board of South Africa in 1989. Updated and refined to suit modern building requirements, the system has held a Agrèment Certificate since 2011.

AREAS OF USE

This system was originally designed, manufactured and constructed for use as dwellings, crèches & school classrooms, studios, offices, garages and stores. Further refinements have been introduced through the years and the system has been extensively used in the affordable (low cost) and Gap housing markets with thousands of modular houses completed and occupied by satisfied owners.

The system is ideally suited to the mass-housing market. Sufficient scale allows for efficiencies that would otherwise not be possible using conventional building methods. Please Note: One-off buildings or home renovations are not viable.

What is the Concretex Housing System?

The Concretex Housing system represents a unique construction method, designed in Africa, for Africa. The challenges of the African housing market should not be underestimated. The problems of housing shortages, coupled with the need for job creation and a general skills shortage are common. These problems require innovative thinking and innovative, holistic solutions.

Constructed using a light-weight ‘Thermo-panel’, the ‘Core’ system provides the bedrock of a home which is thermally efficient, of high quality and speedily erected. The simplicity of the precast concrete system requires minimal on-site training and, in-turn, facilitates job-creation through the co-opting of local communities.

Made out of Cellular Lightweight Concrete (CLC) the ‘Thermo-panel’ provides a lightweight building material at almost half the weight of equivalent dense concrete. The compressive strength of concrete is similar to conventional building blocks while further reinforced with steel mesh throughout. This ensures no compromise in quality when compared to conventional methods.

The external concrete walling panels are manufactured in a quality-controlled factory environment. These are manufactured to exact customer requirements with all electrical and plumbing services cast into the panel. The thermo-panel is significantly lighter than standard dense concrete. This allows the panel to be transported to the site and placed in under an hour. Panels are then fixed together and, depending on the type of roofing required, gable-ends can be added. The structure can accept any standard roofing system.

How does it work?

The position of doors and windows are according to customer requirements and sizes are designed to fit standard components available at any hardware store.

With all service conduits cast in the concrete panel there is no need for chasing. Much of this finishing can be completed by semi-skilled labour with plumbers and electricians only needed for connection.

The smooth finish on the wall panels do not require plastering and paint can be applied directly to the surface.

Internal walls can be built using conventional blocks or, for improved thermals and ease of handling, a CLC block is also available from Concretex. These have high workability, similar to wood.

What is Cellular Lightweight Concrete?

Cellular Lightweight Concrete (CLC), also called Aerated or Foam Concrete, has been in use for over 85 years. It is made by capturing and incorporating bubbles of air into the concrete element. Originally developed in Germany, it provides a unique combination of:

- Strength

- Low Weight

- Thermal Insulation

- Sound Absorption

- Fire Resistance

- Build-Ability

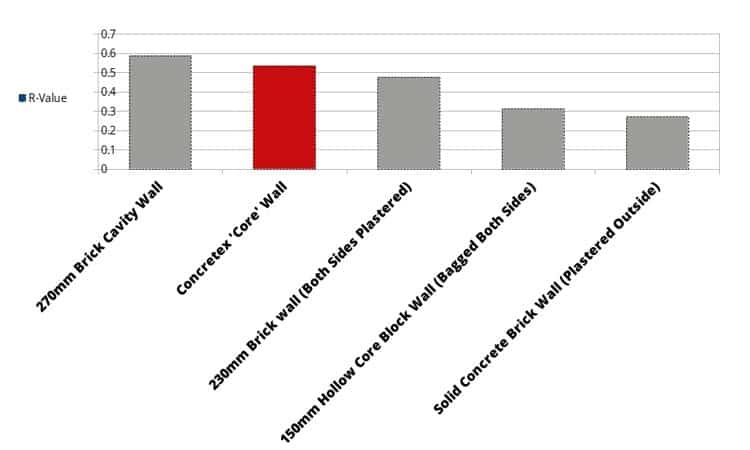

By using CLC, the ‘Core’ system offers all these benefits. Most significant is perhaps the thermal characteristics which, as shown above, are a significant improvement over conventional building systems. This can translate into a significant reduction in heating or cooling costs of between 25% -30%.

Got a project in mind?

For precast house prices in south africa contact us